Multi-Material “Laser” 3D Printer: Crafting Complex Devices in One Go

Behold the 3D printer that munches on plastic, metal, and chips to print wonders in layers!

According to many, what has been popularly regarded as a giant technological leap is now here: the world’s very first 3D printer able to process plastic, metal, and electronic chips to form complex layered devices. The new innovation is likely to change the face of manufacturing and design forever, with endless possibilities for industries and hobbyists alike. Let’s explore the groundbreaking features and possible impacts of this extraordinary 3D printer.

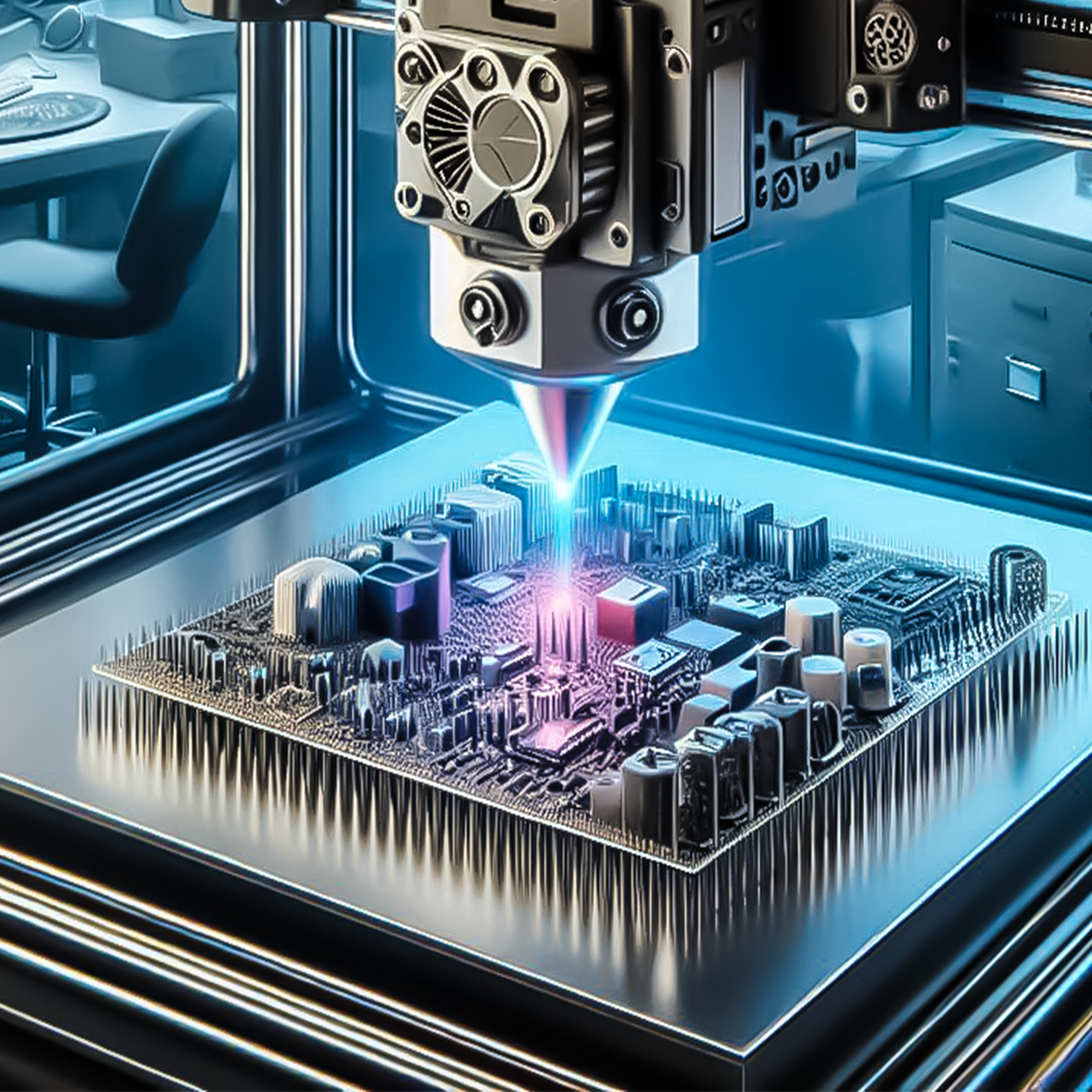

The Printer Technology

1. Processing of Various Materials

This 3D printer is special in that it can handle various materials processing, from plastics and metals to electronic chips. Such materials can be combined in one print to achieve advanced devices with multiple and complicated functions, which cannot be achieved using any other method within traditional manufacturing.

2. Fabrication of Layered Devices

It excels in having layered fabrication, which allows the realization of designs of higher complexity with several integrated components. This enables the fabrication of parts and devices as simple as plastic components and as sophisticated as complex electronic devices within one print process.

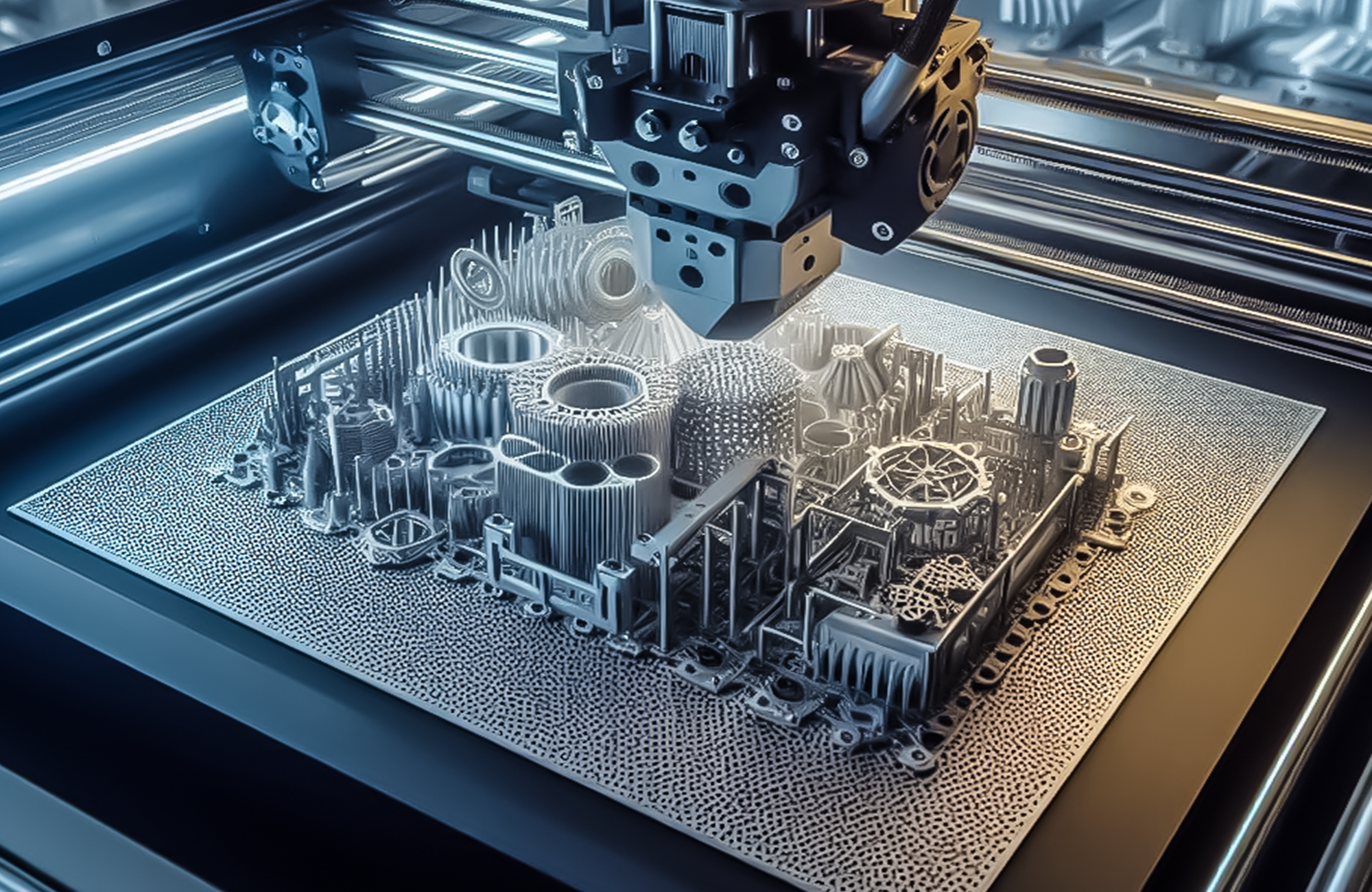

Applications and Industry Impact

1. Prototyping and Manufacturing

The technology can immensely benefit industries such as the aerospace, automotive, and electronics industries in rapid prototyping and the generation of fully functional prototypes at a single print cycle. This accelerates innovation and shortens time-to-market.

2. Custom and On-Demand Production

It has helped in the fabrication of customized parts and devices in demand, which is a very versatile function. This feature makes this process of digital fabrication particularly useful within industries like medical devices, where it is possible to readily print personalized solutions to meet the transformed need of patients.

Ecological and Economic Advantages

1. Material Efficiency

With a wide array of materials all in one device, the printer has maximized its potential for waste reduction and material efficiency. All this minimizes costs and reduces the ecological footprint created as a result of the traditional manufacturing processes.

2. Localized Manufacturing

The ability to create intricate devices at a site minimizes the need for extended supply chains, cutting carbon footprint from transportation. Local production enhances economic growth by allowing small companies to enter into competition with device manufacturers of higher scales.

Challenges and Future Prospects

1. Technological Refining

While impressive, there is still much needed refinement for this printer in order to increase reliability and precision. With further advances in technology, we may well see even more extensive integration of disparate materials and evermore complex print processes.

2. Market Adoption

Awareness and education will define adoptability for public and market demand. Much in demonstrating advantages and potential applications will be very instrumental in the adoption of this revolutionary printer by both industries and consumers at large.

Conclusion

This will, therefore, be the first-ever 3D printer that can process plastic, metal, and chips all at once. In manufacturing and design, the innovation will establish a milestone. The machine is versatile; hence, it is bound to revolutionize industries, spur innovation with sustainability, and usher in a new era in technology.

Looking forward to staying ahead in the future of 3D printing innovation!

This technology will redefine what’s possible in manufacturing

merging multiple materials in a single print for

unprecedented complexity and functionality.

– Industry Expert

What crazy gadget would you create if you had this 3D printer at home? 🖨️🔧

Share your thoughts in the comments below!